The Algorithmic Shift: Examination of AI's Impact on the Future of Manufacturing Work

- Phoenix

- Mar 22, 2025

- 9 min read

Updated: Dec 2, 2025

🏭 Crafting "The Script for Humanity": Navigating Job Transformation and Empowering the Workforce in Intelligent Production

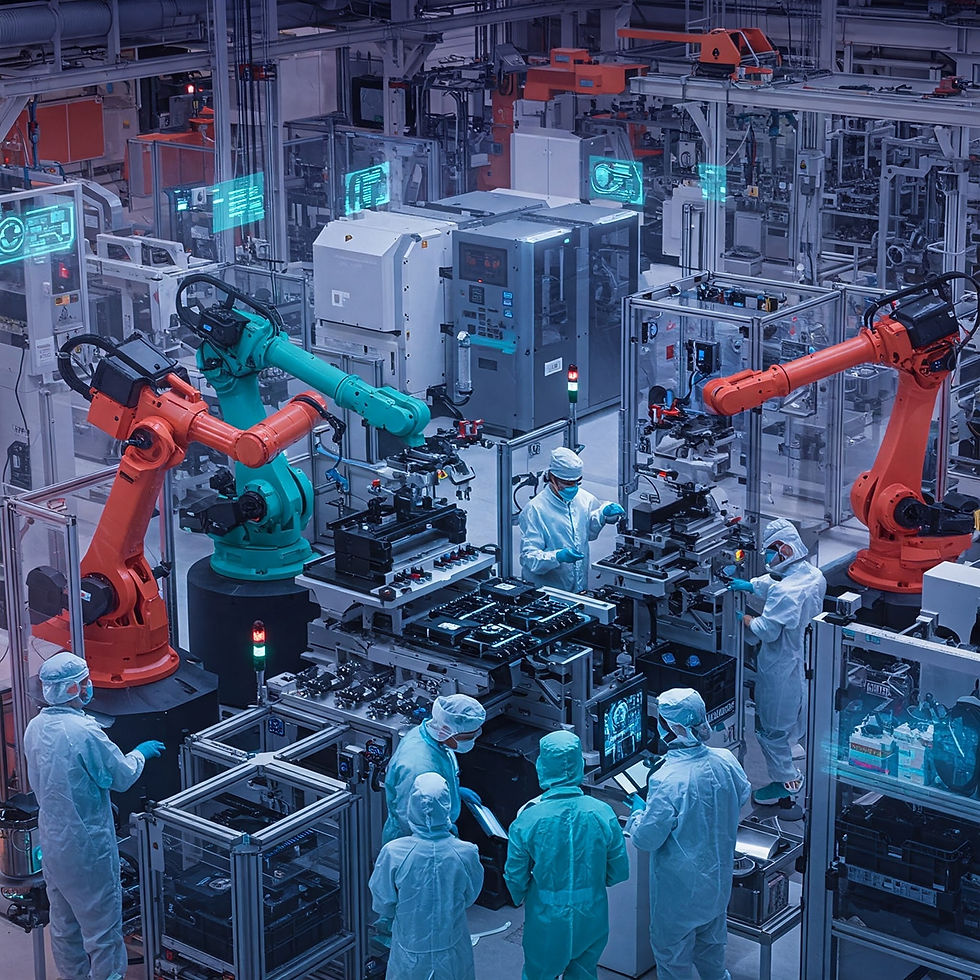

The manufacturing sector, a cornerstone of global economies, is in the throes of a profound "algorithmic shift". Artificial Intelligence is no longer a peripheral technology but a central force, fundamentally altering not just production processes but the very nature of work, the skills required, and the roles humans play on the factory floor and beyond. This transformation, driven by intelligent automation and human-AI collaboration, brings immense potential for increased productivity, innovation, and safety. However, it also presents significant challenges for the workforce. "The script that will save humanity" in this context is our essential, proactive strategy—a blend of ethical principles, educational reform, social policies, and human-centric job design—to ensure this algorithmic shift empowers workers, fosters sustainable industries, and leads to shared prosperity rather than widespread displacement and inequality.

This post examines the multifaceted impact of AI on the future of manufacturing work, exploring the automation of tasks, the augmentation of human capabilities, the emergence of new roles, and the critical "script" needed to navigate this transition humanely and constructively.

🤖 Automation's Advance: AI Taking the Helm of Routine Manufacturing Tasks

AI-powered automation is increasingly handling tasks that are repetitive, physically demanding, or require high precision, leading to significant changes in factory operations.

Robotic Process Automation (RPA) and Intelligent Robotics: AI enhances traditional robotics, enabling machines to perform complex assembly, welding, painting, and material handling tasks with greater adaptability and precision than ever before. This includes intricate tasks in electronics assembly or heavy lifting in automotive plants.

AI-Driven Quality Control and Inspection: Advanced computer vision systems, powered by AI, continuously monitor production lines, identifying defects, anomalies, or deviations from quality standards with superhuman speed and accuracy, reducing the need for manual inspection of every item.

Automated Material Handling and Logistics: Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) navigate factory floors to transport materials, components, and finished goods, optimizing internal logistics and reducing manual CARRYING.

Impact on Traditional Roles: This wave of automation inevitably leads to a reduction in demand for certain traditional manual labor roles focused on repetitive tasks, necessitating a shift in workforce skills and focus.

🔑 Key Takeaways for this section:

AI is driving advanced automation of routine, repetitive, and physically demanding tasks in manufacturing.

This includes robotic assembly, AI-powered quality inspection, and autonomous material handling.

While boosting efficiency, this trend is displacing certain traditional manual labor roles.

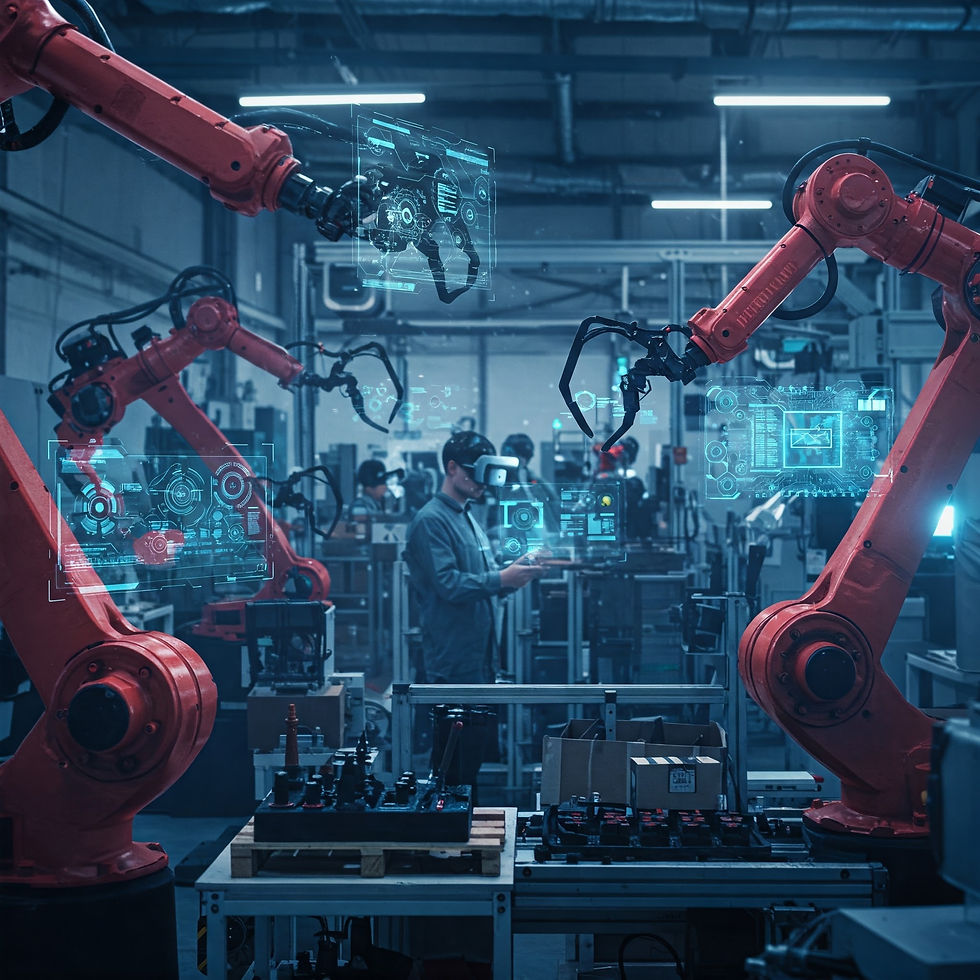

🤝 The Rise of the Augmented Worker: Human-AI Collaboration on the Factory Floor

While some tasks are automated, AI is also emerging as a powerful partner, augmenting the capabilities of human workers and creating new forms of collaboration.

AI as a "Co-Pilot" for Skilled Technicians: AI systems provide real-time data, diagnostic insights, and decision support to human operators and technicians. For example, augmented reality (AR) overlays guided by AI can provide step-by-step assembly or maintenance instructions directly in a worker's field of view.

Collaborative Robots (Cobots): Cobots are designed to work safely and effectively alongside human employees, taking on physically strenuous or highly repetitive parts of a task, while humans handle aspects requiring dexterity, critical judgment, or complex problem-solving.

Empowering Workers with Data and Insights: AI tools can analyze production data to give workers immediate feedback on their performance or process efficiency, empowering them to make adjustments and contribute to continuous improvement.

Enhanced Decision-Making: AI can process complex variables and suggest optimal parameters for machinery or processes, which human workers can then validate and implement, leading to better outcomes.

🔑 Key Takeaways for this section:

AI is increasingly augmenting human workers, acting as a "co-pilot" with real-time data and guidance.

Collaborative robots (cobots) are enabling new forms of human-robot teamwork on the factory floor.

This augmentation aims to enhance human capabilities, improve decision-making, and increase job satisfaction in new ways.

💡 New Roles Emerging from the Algorithm: The AI-Specialized Manufacturing Workforce

The algorithmic shift is not just about changing existing jobs; it's also about creating entirely new roles and career paths within the manufacturing sector.

AI System Operators and Supervisors: As factories become more automated, there's a growing need for skilled personnel to operate, monitor, and manage these complex AI-driven systems and robotic fleets.

Robotics and AI Maintenance Technicians: Specialized technicians are required to maintain, troubleshoot, and repair sophisticated AI-powered machinery and robotic systems.

Manufacturing Data Scientists and Analysts: Professionals who can collect, analyze, and interpret the vast amounts of data generated by smart factories are crucial for optimizing processes, improving quality, and driving innovation.

Human-Robot Interaction (HRI) Designers and AI Ethicists: As human-AI collaboration becomes more common, roles focused on designing intuitive and safe HRI, as well as ensuring the ethical deployment of AI in manufacturing, are emerging.

🔑 Key Takeaways for this section:

The integration of AI is creating new job roles focused on operating, maintaining, and optimizing intelligent manufacturing systems.

Demand is growing for manufacturing data scientists, AI specialists, and HRI designers.

These new roles often require a blend of technical expertise and understanding of manufacturing processes.

🧠 The Evolving Skillset: Adapting to the Demands of Intelligent Manufacturing

The future of manufacturing work demands a significant evolution in the skills valued in the workforce.

Shift from Manual Repetition to Technical Proficiency: While demand for manual dexterity in highly repetitive tasks may decrease, there's a rising need for technical skills, including operating AI-driven machinery, basic data interpretation, understanding digital interfaces, and even rudimentary programming or system configuration.

The Premium on Uniquely Human "Soft Skills": As AI handles routine analytical and physical tasks, uniquely human competencies become even more critical. These include:

Critical Thinking & Complex Problem-Solving: Diagnosing and resolving novel issues in automated systems.

Creativity & Innovation: Designing new products, processes, or solutions in collaboration with AI.

Adaptability & Resilience: The ability to learn new technologies and adapt to changing work environments.

Communication & Collaboration: Effectively working in human-AI teams and communicating complex information.

Lifelong Learning as a Necessity: The pace of technological change means that continuous learning and skill development will be an essential aspect of a career in AI-driven manufacturing.

🔑 Key Takeaways for this section:

The future manufacturing workforce requires a shift from repetitive manual skills to technical and digital competencies.

Uniquely human skills like critical thinking, creativity, and adaptability are becoming increasingly valuable.

A commitment to lifelong learning and continuous upskilling is essential for all manufacturing professionals.

🛡️ Enhancing Workplace Safety and Well-being through AI (If Done Right)

AI has the potential to create significantly safer and healthier work environments in manufacturing, but this requires careful and ethical implementation.

Automating Hazardous Tasks: AI-powered robots can take over tasks that are physically dangerous, ergonomically challenging, or involve exposure to hazardous materials, reducing workplace injuries and illnesses.

AI-Powered Safety Monitoring: Computer vision and sensor systems with AI can monitor the factory floor for unsafe conditions, detect near-misses, ensure adherence to safety protocols (e.g., use of PPE), and alert supervisors to potential hazards.

The "Script's" Caution on Surveillance: While AI monitoring can enhance safety, our "script" demands that it is implemented transparently and ethically, avoiding intrusive surveillance that undermines worker privacy or creates undue performance pressure. The focus must always be on safety and support, not punitive action.

Ergonomic Support: AI can inform the design of more ergonomic workstations or guide the use of assistive devices (like exoskeletons) to reduce physical strain on human workers.

🔑 Key Takeaways for this section:

AI can significantly improve workplace safety by automating hazardous tasks and monitoring for unsafe conditions.

It has the potential to enhance worker ergonomics and reduce physical strain.

Ethical implementation is crucial to ensure AI safety monitoring respects worker privacy and dignity.

🧭 Charting a Just Transition: The "Script" for Workforce Empowerment and Ethical Adaptation

Navigating the algorithmic shift in manufacturing work humanely and effectively is a cornerstone of "the script that will save humanity." This requires proactive, collaborative strategies:

Massive Investment in Lifelong Learning & Proactive Reskilling/Upskilling: Governments, educational institutions, and businesses must collaborate to provide accessible, high-quality training programs aligned with the future skill needs of intelligent manufacturing. This includes apprenticeships, vocational training, and pathways for continuous learning.

Robust Social Safety Nets and Support Systems: For workers whose roles are displaced by automation, comprehensive social safety nets, career transition support, and potentially new economic models (e.g., discussions around Universal Basic Income in some contexts) are essential to ensure no one is left behind.

Ethical AI Deployment in Workforce Management: Any AI systems used for task allocation, performance monitoring, or other workforce management functions must be transparent, fair, auditable for bias, and respect worker autonomy and privacy. Human oversight is critical.

Fostering Human-Centric Job Design: As AI automates tasks, new and redesigned roles should focus on leveraging human strengths—creativity, empathy, complex problem-solving, ethical judgment—creating work that is engaging, empowering, and well-compensated.

Inclusive Dialogue and Worker Participation: Workers and their representatives must be active participants in shaping the AI transition in their workplaces, ensuring their voices, concerns, and expertise are integral to the process.

This proactive and human-centered approach is vital for ensuring the benefits of AI in manufacturing are broadly shared.

🔑 Key Takeaways for this section:

The "script" demands massive investment in lifelong learning, reskilling, and robust social safety nets to support workforce transitions.

Ethical AI deployment in workforce management must ensure fairness, transparency, and respect for worker autonomy.

Human-centric job design and inclusive dialogue with workers are crucial for a just and positive transformation.

✨ Manufacturing a Better Future of Work: AI, Humanity, and "The Script" in Concert

The algorithmic shift driven by Artificial Intelligence is undeniably transforming the landscape of manufacturing work. It presents a future of immense productivity, unprecedented innovation, and potentially safer, more engaging roles for human workers. However, this positive vision is not guaranteed. It can only be realized if we diligently follow "the script that will save humanity"—a script built on ethical principles, proactive societal adaptation, a commitment to lifelong learning, and an unwavering focus on human dignity and well-being. By ensuring that AI serves to augment human capability, create new opportunities, and share prosperity equitably, we can manufacture a future where intelligent production and an empowered human workforce thrive in concert, building a better world for all.

💬 What are your thoughts?

What new skill do you believe will be most crucial for manufacturing workers in an AI-driven future?

What is the most significant societal challenge we must address to ensure a just transition for the manufacturing workforce amidst increasing automation?

How can businesses best foster a culture of human-AI collaboration that empowers employees on the factory floor?

Share your insights and join this vital conversation on the future of work!

📖 Glossary of Key Terms

AI in Manufacturing Work: 🏭 The application of Artificial Intelligence technologies to automate tasks, augment human capabilities, create new job roles, and transform skill requirements within the manufacturing sector.

Workforce Transformation (AI in Mfg): 👥 The significant changes in the nature of jobs, required skills, employment structures, and worker experiences resulting from the widespread adoption of AI and automation in manufacturing.

Human-Robot Collaboration (Cobots in Mfg): 🧑🔧🤝🤖 The direct and safe interaction between human workers and collaborative robots (cobots) on the factory floor, where tasks are shared to leverage the strengths of both.

Skill Gap (AI Era in Mfg): 🧠 The mismatch between the skills possessed by the current manufacturing workforce and the new skills demanded by AI-driven, intelligent production systems.

Reskilling/Upskilling (for AI in Mfg): 📚 Educational and training initiatives designed to equip manufacturing workers with the new competencies (technical, digital, soft skills) needed to thrive in AI-augmented roles.

Ethical AI in Employment (Mfg): ❤️🩹 Moral principles and practices guiding the deployment of AI in manufacturing workforce management, ensuring fairness in hiring and task allocation, protecting worker privacy, and promoting well-being.

Algorithmic Management (Mfg): ⚙️ The use of AI algorithms to assign tasks, monitor performance, and make decisions regarding human workers in a manufacturing environment, requiring careful ethical oversight.

Just Transition (AI in Mfg): 🌱 Societal and economic strategies aimed at ensuring that the shift towards AI-driven automation in manufacturing is managed fairly, providing support, retraining, and new opportunities for affected workers and communities.

Augmented Worker (Mfg): 💡 A human worker whose capabilities, decision-making, and efficiency are enhanced by AI-powered tools, data insights, or collaborative robotic systems.

Industry 5.0: ✨ An emerging paradigm for industry that emphasizes human-centricity, sustainability, and resilience, where AI and technology are designed to work alongside and empower human workers, rather than simply replacing them.

Posts on the topic 🏭 AI in Manufacturing and Industry:

The Human-Free Factory: Who Are We When AI Does All the Work?

Production Power Play: 3D Printing vs. Traditional Manufacturing

Industrial Intelligence: 100 AI Tips & Tricks for Manufacturing & Industry

Manufacturing & Industry: 100 AI-Powered Business and Startup Ideas

Manufacturing and Industry: AI Innovators "TOP-100"

Manufacturing and Industry: Records and Anti-records

Manufacturing and Industry: The Best Resources from AI

Statistics in Manufacturing and Industry from AI

The Best Tools AI in Manufacturing & Industry

Strategic Implementation AI in Manufacturing - A Hyper-Detailed, Quantum-Informed Exploration

The Algorithmic Shift: Examination of AI's Impact on the Future of Manufacturing Work

The AI Factory: Remodeling Manufacturing from the Ground Up

The Algorithmic Architect: Exploration of AI's Quantum Leap in Manufacturing

AI in Manufacturing

Comments