From the Hammer Strike to the Digital Twin: Forging the Future

- Phoenix

- Dec 10, 2025

- 7 min read

Updated: Dec 11, 2025

💡 AiwaAI Perspective

"For millennia, the act of creation was a battle between human muscle and raw matter. We hammered, forged, and carved the world into shape through sweat and danger. We believe that Industry 4.0 represents the awakening of the machine. It is the moment where the factory ceases to be a dumb collection of gears and becomes a sentient nervous system. The goal is not just to produce more, but to produce with zero waste, infinite variety, and absolute precision—turning the 'dumb' assembly line into a 'smart' partner."

🧬🏭 Industry 4.0: When factories begin to think for themselves.

Imagine standing in a foundry in Sheffield, England, 1850.

The air is thick with coal smoke. The noise of steam hammers is deafening. Men with blackened faces wrestle molten steel, risking their lives for pennies. Production is an act of brute force. Every nail, every rail, every beam is born from heat, danger, and exhaustion. If a machine breaks, the factory stops for days. If a defect is found, thousands of products are scrapped.

Now, fast forward to today. You stand in a "Dark Factory" in Germany. The lights are off because the robots don't need to see. There is no noise, only the soft hum of servos. In the cloud, a "Digital Twin"—a perfect virtual replica of the factory—simulates a production run 1,000 times before a single physical motor moves. The factory predicts a bearing failure three weeks in advance and orders its own replacement part.

This transformation is the shift from Mechanization to Cognition. It is the story of how we taught machines not just to move, but to think. But as the "Lights Out" factory becomes reality, we face a social question: If machines make everything, what is left for the human hands to do?

This is the chronicle of the Iron Mind.

📑 In This Post:

1. 📜 The Grand Timeline (1784 A.D. – 2030 A.D.): The four industrial revolutions.

2. 👯 The Digital Twin: Simulating reality to eliminate error.

3. 🔮 The Machine That Never Breaks: Predictive maintenance and the end of downtime.

4. 🎨 Mass Customization: The end of "One Size Fits All."

5. 🛡️ The Humanity Script: From Operator to Architect: Redefining the value of labor.

1. 📜 The Grand Timeline: The Four Leaps

Industrial history is divided into four distinct "Revolutions," each driven by a new energy or logic.

🏛 Era I: Industry 1.0 (Steam & Water)

We replace muscle with mechanical power.

🚂 1784 — The Power Loom.

Edmund Cartwright designs the first mechanical loom. It is the birth of the factory system. We stop making cloth at home and start making it in centralized halls driven by water or steam.

🔧 1798 — Interchangeable Parts (Eli Whitney).

The realization that every musket trigger should be identical. We move from "Craft" (every item is unique) to "Standardization."

⚙️ Era II: Industry 2.0 (Electricity & Assembly Line)

We speed up the process with flow.

⚡ 1870 — The Cincinnati Slaughterhouse.

The first moving assembly line (for disassembling pigs). It inspires Henry Ford.

🚗 1913 — The Ford Model T Line.

The Turning Point. Ford reduces the time to build a car from 12 hours to 90 minutes. Mass production makes luxury accessible to the masses.

👷 1920s — Scientific Management (Taylorism).

Humans are treated like robot components—measured by stopwatch to optimize every movement.

💻 Era III: Industry 3.0 (Computers & Automation)

We replace the human brain with logic controllers.

🤖 1961 — Unimate.

The first industrial robot joins the GM assembly line. It welds car bodies. It doesn't get tired.

🎛️ 1969 — The PLC (Modicon 084).

The Programmable Logic Controller. Factories run on software logic instead of hard-wired relays. Automation begins in earnest.

🤖 Era IV: Industry 4.0 (Cyber-Physical Systems)

The factory gets a brain.

🌐 2011 — "Industry 4.0" Coined.

The German government introduces the strategy of connecting machines to the Internet (IoT).

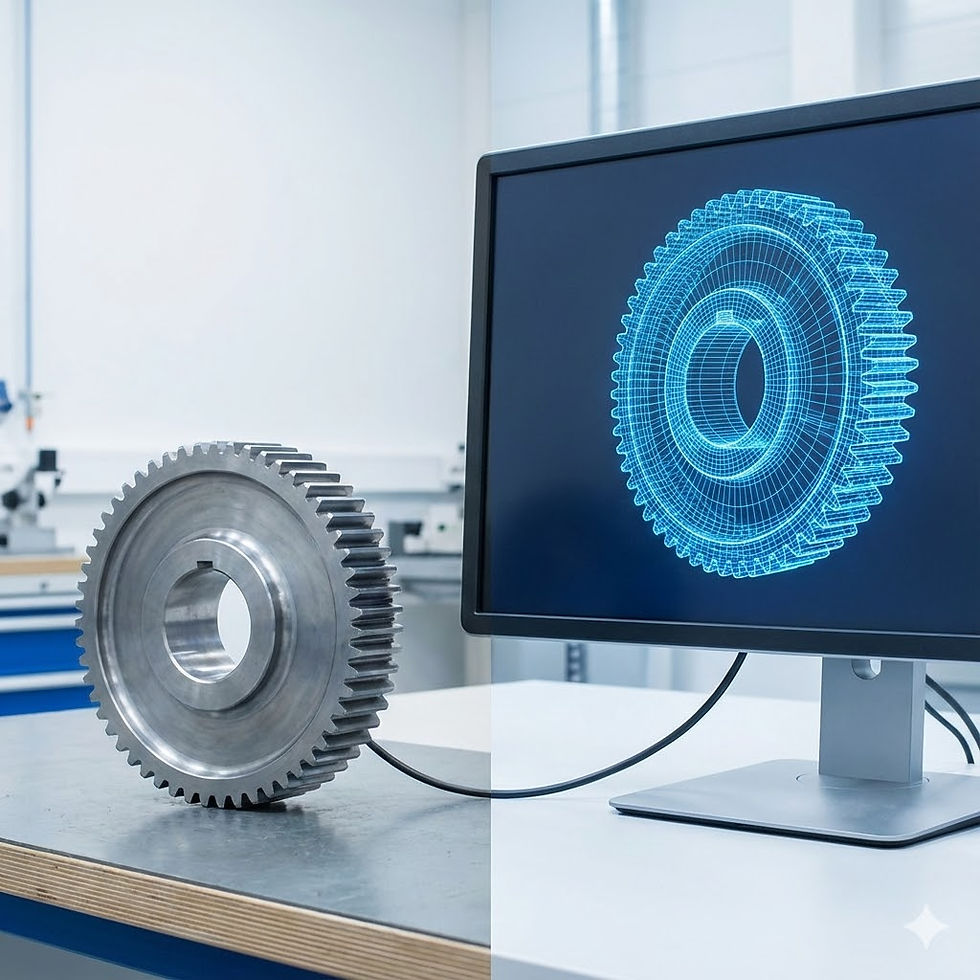

👯 2015 — Digital Twins Emerge.

NASA and GE start using virtual models to monitor physical assets in real-time.

🏭 2025 (Prediction) — The Dark Factory.

Fully autonomous factories where raw materials enter one end and finished products leave the other, with zero human intervention on the floor.

2. 👯 The Digital Twin

In the past, if you wanted to change a production line, you had to shut it down, move heavy machines, and pray it worked. It was expensive and risky.

The Shift: Simulation First.

The Mirror World: A Digital Twin is a virtual ghost of the factory. It runs in the cloud, mirroring every sensor, every belt, and every temperature reading of the real factory.

Time Travel: Engineers can fast-forward the Twin. "What happens if we increase speed by 20%?" The simulation shows a motor overheating in 4 hours. The engineers fix the problem in the virtual world before it ever happens in the real world.

3. 🔮 The Machine That Never Breaks

"Downtime" is the enemy of industry. If a $10 million line stops because a $5 fan broke, the company loses thousands of dollars a minute.

The Shift: Predictive Maintenance.

The Voice of the Machine: Old machines ran until they broke. Smart machines listen to themselves. Vibration sensors detect that a bearing is wobbling by 0.001mm—imperceptible to a human, but a clear sign of failure in 2 weeks.

Self-Healing: The machine alerts the maintenance team (or orders the part) before the failure occurs. We move from Repair to Prevention.

4. 🎨 Mass Customization

Henry Ford famously said: "Any customer can have a car painted any color that he wants so long as it is black." Mass production required uniformity.

The Shift: The Batch of One.

Flexible Robotics: AI allows robots to switch tasks instantly. One car on the line is a red sedan; the very next one is a blue SUV. The robot adapts its welding program in milliseconds.

The Impact: We can now have the low cost of mass production with the personalization of a craftsman. Personalized shoes, medicine, and cars become the norm.

5. 🛡️ The Humanity Script: The Architect of Work

This is the great fear: Automation stealing jobs.

If the "Dark Factory" needs no lights, it needs no people.

The Humanity Script:

From Operator to Supervisor: The human role shifts from doing the work (welding, lifting) to designing the work. We become the architects of the system, not the gears within it.

The Return of Craft: As machines take over the utilitarian, "perfect" manufacturing, human imperfection becomes a luxury. "Hand-made" becomes more valuable precisely because a robot didn't make it.

Dignity: We must ensure that the wealth generated by hyper-efficient robots is distributed in a way that dignifies the displaced worker.

Conclusion:

We have moved from the Hammer, which extended our arm, to the Digital Twin, which extends our mind.

The factory of the future is not a place of grime and noise. It is a quiet, clean temple of efficiency. Our job is no longer to be the machine, but to dream up what the machine should build next.

💬 Join the Conversation:

The Choice: Would you pay extra for a chair made by a human carpenter over one made perfectly by a robot? Why?

The Fear: Do you believe "Dark Factories" will lead to mass unemployment, or a world where humans don't have to do dangerous jobs?

The Future: If AI can manufacture anything instantly, does "materialism" lose its meaning?

📖 Glossary of Key Terms

🏭 Industry 4.0: The current trend of automation and data exchange in manufacturing technologies (IoT, cloud computing, AI).

👯 Digital Twin: A virtual model designed to accurately reflect a physical object, allowing for simulation and monitoring.

🔮 Predictive Maintenance: Using data analysis to detect anomalies in equipment and fix them before they result in failure.

🌑 Dark Factory: A fully automated production facility that requires no human presence on site (and thus no lighting/heating for humans).

🎛️ PLC (Programmable Logic Controller): An industrial digital computer that has been ruggedized and adapted for the control of manufacturing processes.

Posts on the topic 🧬 Evolution: From Stone to Code:

From the Cave Fire to the Neural Network: The Grand Timeline of Comfort

From Clay Tablets to Neuro-Tutors: The Awakening of Human Potential

From Shamanic Rituals to Rewriting DNA: How We Learned to Cheat Death

From the Clay Ledger to the Blockchain Oracle: The Evolution of Value

From the Silk Road to Teleporting Matter: Victory Over Distance

From the Hammer Strike to the Digital Twin: Forging the Future

From the Grand Bazaar to Predicting Desires: The Evolution of Trade

From Rain Prayers to Planetary Gardening: The Great Battle for Bread

From Campfire Tales to Infinite Dreams: The New Era of Storytelling

From Stone Walls to the Iron Dome: The Shield of Civilization

From Prometheus' Fire to the Artificial Sun: The Chase for Infinite Energy

From the Code of Hammurabi to Algorithmic Justice: The Search for Absolute Truth

From Scribe Scrolls to the Sentient City: Governance 2.0

From Alchemy to Digital Simulation: Accelerating Cognition

From Stargazing to the Ark of Humanity: The Expansion of Reason

From Smoke Signals to Digital Telepathy: Weaving the Global Web

From Conquering Nature to Harmony with It: The Great Restoration of Earth

From Cloud Divination to Taming the Storm: The Prediction Revolution

From Mud Huts to Living Organisms: The Birth of the Conscious City

From the Town Crier to the Soul Reader: The Art of Connection

From Animal Skins to Digital Couture: The Fabric of Identity

From the Pyramids of Giza to Self-Assembling Buildings: The Architecture of a New World

From Cave Paintings to the Infinite Canvas: The Democratization of Creativity

From Dice to Living Simulations: Engineering Realities

From the Tower of Babel to Universal Understanding: Shattering the Walls of Silence

From Tribal Instincts to the Global Hive: Deciphering the Human Code

From Pilgrims to Experience Curators: The Art of Discovery

From the Assembly Line to Talent Architecture: Liberating the Creator

Comments